AUTOMATIC CASE PACKING

Solving Complexity with Engineering and Experience

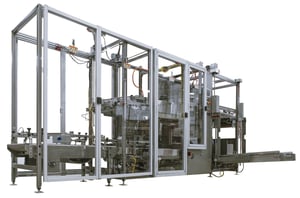

Seamless Transition from Case Erecting to Product Loading

Once the foundation of case erection has been established, the next process to upgrade in your packaging automation journey is getting your products into the case. Performing this task manually has the same fundamental drawbacks of any process that relies primarily on human involvement: throughput is slow, quality is inconsistent, and the headaches and costs associated with labor are painful. Automating the case packing process addresses these deficiencies but presents a complex challenge that must be met with a combination of product capabilities and, just as importantly, specific knowledge that only comes from experience. At Combi, we understand that each application is unique. Successful case packing requires expertise in material handling to ensure your products are effectively oriented and presented prior to loading as well as integration know-how to coordinate upstream and downstream processes. Additionally, Combi’s case packing portfolio is not limited to a single technology unlike some other companies in the industry. We can bring to bare a full range of options to provide the best solution depending on your product format, mix, production speed requirements, floor space constraints, and budget.

Tailored Solutions for Diverse Challenges

1. Drop Packers: Engineered for both speed and accuracy, our drop packers are the pinnacle of high-throughput packaging. Products are presented above an open case before being gently “dropped”. Our Drop Packers are available with an integrated case erector to minimize cost and footprint with models capable of speeds up to 30 cases per minute. We also offer standalone drop packers that can be fed from an independent case erector capable of speeds up to 50 cases per minute.

2. Pick and Place Packers: For more delicate or precise placement requirements, our Pick and Place systems offer unmatched performance. Utilizing an automated arm equipped with custom tooling, this system picks products from an infeed conveyor and carefully places them into awaiting cases staged on a parallel conveyor. Our well-known Alphapack series, which includes an integrated case erector, and the standalone SPP line both support speeds up to 20 cases per minute, combining precise product handling with swift production rates.

3. Horizontal Loaders: Some products require a horizontal packing approach due to their shape or orientation sensitivity. Combi's horizontal loaders are specifically designed for such applications and are available with or without integrated case erectors and capable of managing up to 8 cases per minute, ensuring even the most uniquely shaped products are packed with precision.

4. Robotic Systems: For the most complex and varied packing needs, Combi’s robotic solutions stand at the forefront of technology. As a certified Fanuc integrator, we leverage a wide range of collaborative and industrial robots, tailoring each system to package products with exceptional reliability, speed, and flexibility.

Built for the Real World to Deliver Real Results

While each case packing solution is different, they all share the same Combi characteristics that make them well-suited for success in an actual production environment:

- An uncompromising focus on safety

- Heavy duty construction that is designed for maximum reliability

- Compact footprint to minimize floor space requirements

- Fast and easy changeovers enhancing flexibility

- User friendly with an intuitive HMI and simple mechanical adjustments

- Excellent value that delivers a significant return on investment

By choosing Combi, you’re not just selecting a machine; you’re partnering with a leader in packaging with a deep-rooted history of innovation. Our experience, coupled with an unwavering dedication to solving your packaging challenges, ensures that every case is a showcase that you can be proud of.

Search Automated Case Packing Systems by Maximum Speed:

.png?width=161&name=ProWrap%20(1).png)