The Combi Ergopack System

Streamlining Packaging with Smart Automation

Innovative Packing Solution for Modern Needs

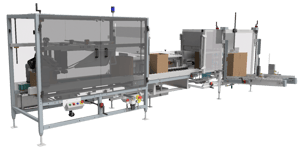

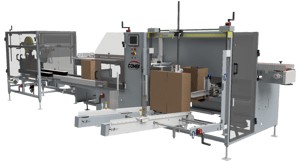

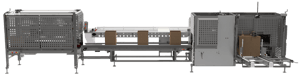

As a standout offering in our product line, the Combi Ergopack system represents the pinnacle of semi-automatic packing solutions. Designed to efficiently streamline the packing process, the Ergopack system integrates multiple packaging operations into a single system, combining case erecting, packing, and sealing into an optimized workflow.

Flexible Performance Across Industries

The Ergopack system is engineered to accommodate a diverse range of case sizes and types, making it suitable for various industries from food and beverage to outbound logistics. With models capable of handling 10 to 30 cases per minute, this system ensures high productivity while maintaining consistency and reliability. Its modular design allows for easy integration into existing production lines, enhancing flexibility and reducing the need for extensive layout changes. The system is perfect for operations that manage a diverse array of products where full automation is not feasible, such as co-packing environments or applications that require manual handling of products that are fragile in nature or need precise orientation.

Tailored to Fit Every Application

Each Ergopack model is designed with customization in mind, allowing it to meet the specific requirements of different production environments. Whether your operation demands compact solutions for limited spaces, high-speed setups for large-scale production, or full washdown construction for harsh food packaging environments, the Ergopack system can be configured to suit your needs. This adaptability makes it an invaluable tool for businesses looking to maximize their investment in automation without compromising on quality.

Ergonomic Design for Enhanced Operator Comfort

Recognizing the importance of operator comfort and safety, the Ergopack system features ergonomic design principles that reduce the physical strain associated with legacy manual packing processes. By minimizing repetitive motions and optimizing operator positioning, the Ergopack system not only enhances safety but also improves overall job satisfaction and productivity. Operators simply focus on the process of loading cases which allows them to do it faster, more accurately, and with greater endurance.

Seamless Integration with Advanced Features

The Ergopack system is equipped with advanced features, such as an Allen Bradly control package and servo motors, that ensure seamless integration and ease of use. From intuitive control interfaces to straightforward adjustments for different case sizes, each element is designed to simplify the packing process. The system's reliability is further enhanced by high-quality components and robust construction that withstand the punishment of continuous industrial use.

A Proven Asset in Streamlining Operations

Adopting the Combi Ergopack system translates into tangible benefits for your business, including significant labor savings, reduced packaging material waste, and a faster return on investment. Its proven track record of enhancing packaging line efficiency makes it a trusted choice for companies aiming to stay competitive in fast-paced markets. It’s no wonder that the Ergopack system is one of our most popular product offerings!

Explore the Potential of Ergopack

Discover the advantages of integrating the Combi Ergopack system into your packaging line. For more details, a consultation, or a live demonstration, contact us today and let us show you how Combi can help streamline your operations with our customized, ergonomic, and reliable packaging solutions.

Search Ergopack Systems by Maximum Speed:

Most Popular Ergopack Systems at a glance

~150 Cases

~150 Cases

~150 Cases

~150 Cases

~150 Cases

Frequently Asked Questions

Ergonomic packing operations reduce physical stressors associated with manual hand packing. This can result in lower workers' compensation costs and increased profits from greater productivity.

Hand packing stations feature adjustable legs and components, putting your products in easy reach. A Combi semi-automatic, ergonomic hand packing machine can form, pack and seal while minimizing repetitive motions.

.png?width=161&name=ProWrap%20(1).png)