Case Sealers

Case Closed! Fast, Secure Case Sealing

Diverse Solutions for Every Requirement

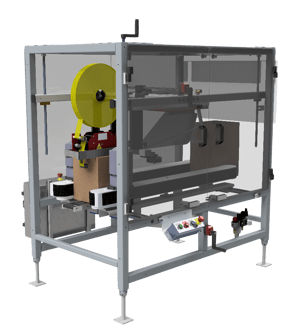

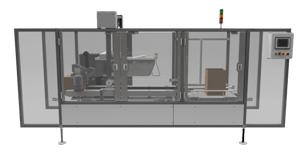

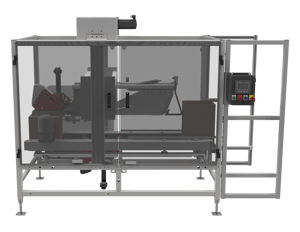

Upgrade the efficiency and reliability of your end-of-line packaging with Combi’s extensive range of case sealers. Designed to handle multiple case sizes, boost production speed, and meet high hygiene standards, our case sealers are tailored to your needs. Whether used alone or integrated into a Combi case erecting and packing line, our compact sealers offer modular flexibility and are supported by industry-leading service.

Combi offers a comprehensive selection of case sealer models tailored to various production rates and case dimensions. Our systems are capable of top or bottom sealing with either tape or hot melt glue, ensuring a secure seal every time. Here’s what makes our sealers a great investment:- Increased Throughput: Our case sealers speed up the sealing process significantly compared to manual methods, allowing for greater production output.

- Reduced Labor Costs: Automate your sealing process to lower manpower costs and minimize the risk of human error and repetitive motion injuries. You will be free to reallocate labor from this unpleasant task to more value-added activities.

- Consistency and Optimization: Automating the sealing process achieves consistent tape placement and eliminates the waste inherent to manual sealing including double-taping, cross-taping, and inconsistent tape lengths. Additionally, Combi case sealers can facilitate moving to a narrower tape width due to enhanced case control and tape head precision resulting in substantial material savings. It’s not uncommon for customers to go from a 3” wide tape and a manual dispenser to 2” wide tape on an automated case sealer.

- Product Protection: Properly sealed cases protect against contamination and damage during shipping and storage, maintaining product integrity. The cost of an improperly sealed case adds up quickly when you consider product replacement, negative customer experience, and environmental impact associated with wasted materials and re-shipping.

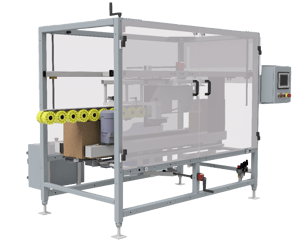

From Semi-Automatic to Fully Automatic

- Semi-Automatic Models: Ideal for smaller or start-up operations, our entry-level semi-automatic sealers require manual feeding of cases into the sealer, perfect for businesses scaling their automation processes.

- Fully Automatic Systems: Integrated seamlessly with upstream processes, these systems provide a hands-off, completely automated sealing solution, designed for high-volume production environments where reliability is essential.

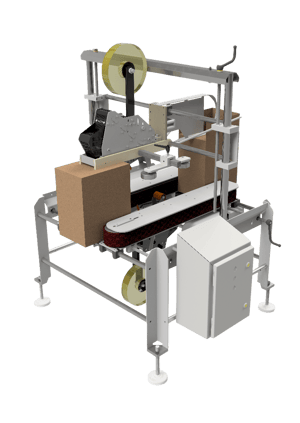

Adaptability with Random Case Sealers

Our random case sealers stand out in facilities with diverse packaging needs, automatically adjusting to different case sizes without manual intervention. This capability is perfect for operations with variable case dimensions, reducing downtime and enhancing flexibility in production scheduling.

Dependable Performance in Demanding Environments

Combi's sealers are not only ruggedly constructed and reliable but also prioritize safety and ease of use. For the rigorous demands of food production, select models are available in full washdown construction, designed to withstand harsh environments while meeting stringent sanitary requirements of RTE (Ready-To-Eat) packing rooms.

Search Case Sealers by Maximum Speed:

Most Popular Case Sealers at a Glance

Frequently Asked Questions

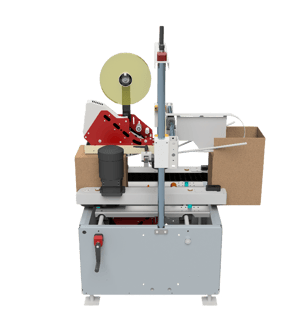

A Combi case sealer (sometimes referred to as a box sealer or box taping machine) provides packaging that holds up to the rigors of transit. Our equipment can handle overlapping or sequentially folded flaps or tuck-folded flaps.

Combi case sealers meet a variety of needs, including sanitary washdown unit options for the food industry. We also offer heavy-duty case sealers and standalone case sealers.

Case sealing machines come in a variety of versions, and Combi can help you find the right one for your needs. We offer both tape sealing machines and hot-melt glue case sealing machines. There are semi-automatic and automatic case sealers. And, we also offer sanitary options for the food industry, as well as heavy-duty case sealing and standalone case sealers.

.png?width=161&name=ProWrap%20(1).png)