.jpg?width=300&name=2-EX%20HS%2020%20(3).jpg)

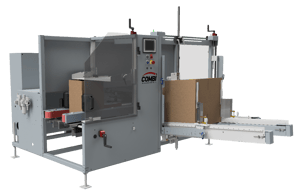

CASE ERECTORS

Efficiency Unfolded. Perfect cases, Every Time.

Transforming the Foundation of End-of-Line Packaging

The cornerstone of any streamlined packaging line begins with efficient case erection. Traditionally, manual case forming has been a bottleneck in operations, plagued by slow production speeds, inconsistent tape usage, and the need to stage formed cases before packing. The average worker can manually form approximately three cases per minute, leading to increased labor costs and potential for human error. Inconsistencies in tape application not only increase the consumable cost but can also compromise the integrity of the case creating the potential for expensive product damage. Additionally, manual processes require significant floor space for staging, which could be better utilized for operational activities.

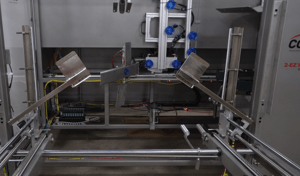

Enter Combi’s Innovative Case Erectors

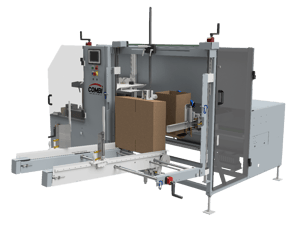

Combi's case erectors have the capability to handle both left-hand (LH) and right-hand (RH) cases on the same unit, providing versatility and efficiency in operation. They also optimize this stage of packaging by combining speed, precision, and reliability, effectively eliminating the inefficiencies of manual operations. Our offering can handle a diverse range of operational budgets and production requirements with models capable of erecting cases at speeds ranging from 10 to over 30 cases per minute. This significant increase in throughput sets the stage for subsequent packaging processes boosting overall productivity.

Big On Uptime and Small on Real Estate

Reliability is at the core of our design philosophy. Combi case erectors are ruggedly built to maximize availability and eliminate unexpected surprises in your production schedule. To complement their workhorse reputation, our erectors are widely known for their compact footprint making them ideal for facilities where space is at a premium, allowing you to reclaim valuable floor space for more productive uses.

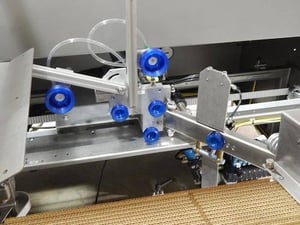

User-Friendly and Adaptable

Ease of use is another distinguishing feature of our case erectors. Equipped with an intuitive HMI and simple mechanical adjustments, our machines are straightforward to operate with minimal training. This user-centric design extends across our broad product offering, which includes hot melt glue sealing options and innovative solutions like a Dual Magazine model that can erect two different case sizes without the need for changeover. Additionally, our Robotic Case Erector can handle up to eight different case sizes on demand, providing unmatched flexibility to meet changing production needs. It’s perfect for outbound e-commerce fulfillment operations where minimizing the package size is critical to reducing dimensional weight shipping charges. Chances are we have a model that is perfect for your application. If not, we love a challenge and are proud of our long history of providing custom solutions especially when others in our industry are unwilling or unable to do so. Put us to the test!

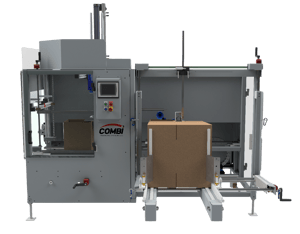

Handling with Care: The Forgiving Nature of Combi Case Erectors

Understanding the realities of corrugated case construction, Combi erectors are uniquely forgiving and capable of handling “less than perfect” cases to keep your production running and avoid the hassles associated with a potential return. Simply put, our systems are generally able to run cases that would cause problems for other equipment manufacturers. We’ve also seen the growing popularity of higher recycled content material to support sustainability initiatives. The physical properties of corrugated board degrade as it goes through the recycling process making it less suitable for automation that prefers consistency and repeatability. Combi systems maximize your chances of success when it comes to handling the variability inherent in this type of material. Additionally, Combi closely monitors industry trends related to sustainability to ensure that our equipment remains compatible and effective.

Search Case Erectors by Maximum Speed:

Most Popular Case Erectors at a Glance

Frequently Asked Questions

With a Combi case erector, you can be more efficient, save on labor and increase production. Combi case erectors give you flexibility for easy changeovers, with options for a variety of product packaging needs. We also design and engineer custom case erectors.

Combi case erectors have the strongest frame in the industry and come with a lifetime warranty. Our case erectors can also be integrated with our case packers, providing a compact solution to load products for shipping.

.png?width=161&name=ProWrap%20(1).png)