Video Library

For videos by industry, check out our industry video library page.

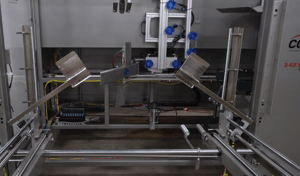

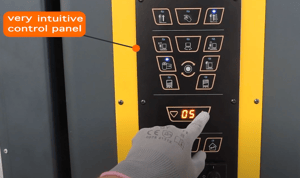

*NEW* 2EZ-A Series Case Erector

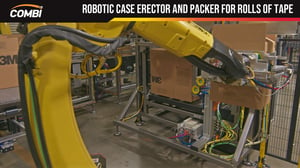

Robotic Case Erector and Packer for Rolls of Tape

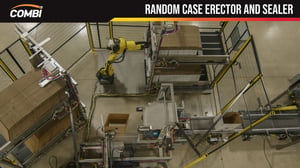

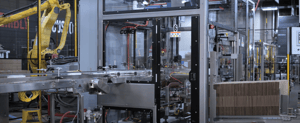

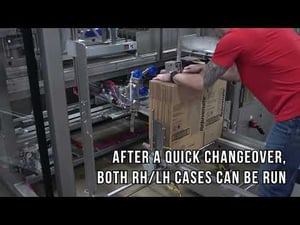

Robotic Random Case Erector with Case Sealer

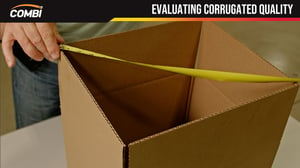

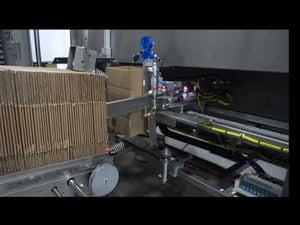

Evaluating Corrugated Quality

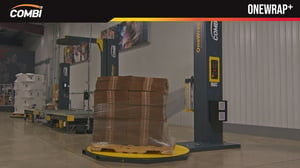

OneWrap+ Stretch Wrapper: Engineered for Performance, Built for Durability

Semi-Automatic Case Packing of Bagged Noodles

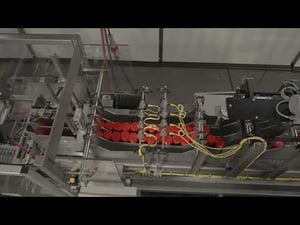

Complete Robotic Case Packing Line for Spices

Combi Spare Parts Support 2025

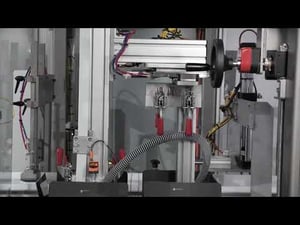

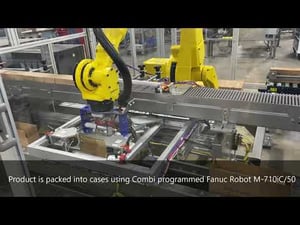

Complete Robotic Packing & Palletizing System: Paint Cans

Combi Overview 2025

Fully Automatic Case Packing System: Frozen Garlic Sticks

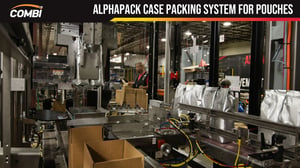

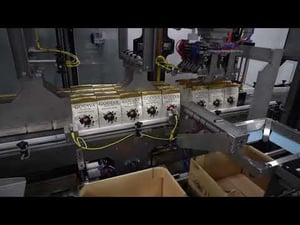

The Alphapack Case Packing System for Pouches: Coffee

Building Strong Relationships and Equipment

Maximize Uptime with Combi’s Expert Support | Preventative Maintenance & Service

Alphapack 10: Biscotti Cookies

OneWrap+ Setup and Startup

TBS-100 XL RTE HS T&B Case Sealer

BeeWrap+ | Wrap Without Limits

Robotic Packer: Deli Meats

DP 10: Canisters of Powdered Creamer

HL XL: Caulking Tubes

BeeWrap+ Wrapping a Case Erector to Ship

Alphapack 10: Honey Bear Bottles

Robotic Packer: Electrical Panels

Robotic Case Packing Line: Packages of Sausage

Alphapack 20: Godiva Chocolates

DPI: Juice Jugs

Robotic Ergopack System: Packages of Chocolate Chips

Ergopack 15 with Puck Conveyor System

Ergopack with HM Case Sealer

Ergopack 15 with Custom Case Turner

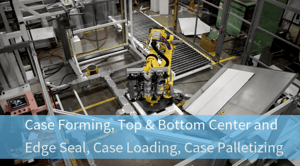

Custom Dual Line Pick and Place Case Packing System with Robotic Palletizer

Sanitary Hand Packing System with Partitions

Yaskawa Robot Case Erector: 5 Large RSC Case Sizes

2-EZ SB Case Erector

Drop Packer with Hot Melt Glue Case Sealer: RSC Cases of Refrigerant

HSE High-Speed Case Erector

High-Speed Drop Packer with Integrated Ergopack: Cans of Aerosol Cleaning Products

Ergobot Robotic Case Packer: Multi-Purpose Scrub Sponges

Alphapack with HM Case Sealer: Chipboard Cartons of Granola Bars

Vertical Loader with Integrated Case Erector: Trays of Fuel Filters

Sanitary Ergopack: Hand Packing System

Robotic Cell: Medical Tape

Robotic Packaging and Automation Innovation Experts

Custom End-of-Line Packaging Solutions: Palletizing Robots

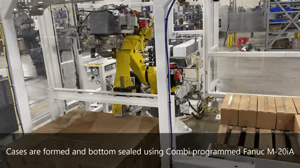

Case Compression: Top & Bottom Case Sealer

High-Speed Ergobot: Bags of Candy

Erect, Pack, Seal, Palletize: Foam Mattresses

High-Speed Drop Packer: Shampoo Bottles

High Speed, 3-Person Ergopack: Yogurt Cups

High-Speed Alphapack: Square Gallon Pails with Handles

2-EZ HS Case Erector

L Clip Case Sealer: Wide Side with Conveyor Modification

Robotic Ergopack: Medical Supplies

HTF Single Stage Tray Former

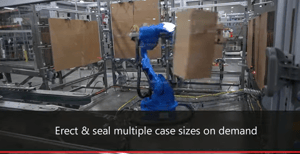

RCE: Robotic Random Case Erecting

HTF: Horizontal Tray Former with Auto Changeover

RCE Robotic Case Erecting: Large Cases

High-Speed SPP with Integrated Hand Packing System: Large Blocks of Cheese

Random TBS-100 Case Sealer: Eggs

Robot Randomly Case Erects 5 Different Large Case Sizes

2-EZ HS HM Case Erector

SPP and Tray Packing: Personal Care Bottles

Random TBS-100 XL Egg Case Sealer

2-EZ HS HM Case Erector: Beverage Fold FOL Case

Random Case Sealer with Crate Bypass

HL: Rolls of Stretch Wrap Film

Robotic System with Case Divider Inserter

4-Person High-Speed Ergopack with HM Case Sealer

Random TBS-100 XL Case Sealer: Eggs

HL Side Loading System: Grease Tubes with Caps

RTE Sanitary Ergopack

SPP System: Containers of Pretzels

Robotic Case Packing and Palletizing with Dual Lines

Robotic Case Packing: 11 Different Bottle Sizes with Inserts and Pamphlets

Ergopack Hand Packing System with Dunnage Shelf

Robotic Case Packing: Frozen Meat

RCE: For a Bottle Ready Case Line

2-EZ HS: No Tape & Reverse Fold

Ergopack with Dual Tape Head: Paper Towels and Toilet Paper

2-EZ SB Standard Ergopack

2-EZ HS Case Erector: Cases with Handles

2-EZ HS Case Erector with Servo Vacuum Extend

Alphapack with Diverter: Canned Food

Alphapack: Protein Powder

2-EZ SB Case Erector: Narrow Case

TBS-100 FC XL Case Sealer: All Pneumatic

E1000 Drop Packer: Aerosol Cans

Ergopack: Auto Changeover

Random Height and Width TBS-100 XL Case Sealer

High-Speed Alphapack: Cans of Cold Brew Coffee

Alphapack HS: Multipacks of Egg Products

Alphapack HS with Vision System: Serialized Medicine Bottles

TBS-100 Case Sealer: Tape or Hot Melt Glue

TBS-100 XL HM Case Sealer

Alphapack: Glass Bottles

Alphapack System with Racetrack In-feed: Suet

Alphapack: Rotating Pick Head

Combi Flap Control on End-of-Line Case Packers

Robotic Palletizer Dual Lanes

HTF 10

Horizontal Case Loader: Grease Tubes

Ergopack 15: Pouches of Hand Soap

Robotic Case Packing System: Athletic Tape

TBS-100R with Bottom Flap Guides

Compact Drop Packer RSC Antibacterial Wipes in Bags

CHL with Product Twist Conveyor: Caulking Tubes

2-EZ XXL Case Erector

Dual Magazine Case Erector

2-EZ XXL Case Erector

2-EZ SB RTE Case Erector

2-EZ HS 20: Stainless Steel Washdown

2-EZ HS: Fulfillment Center

2-EZ SB Case Erector

Bulk Fill System with Optional Hand Packing: Apple Slices

Bulk Fill System | Bags of Coffee

TBS-100R 20 Random Case Sealer

TBS-100 Case Sealer

TBS-500 Case Sealer

DPI System with Two Case Erectors: Spray Paint

DP 12: Glass Bottles

DP 12: Disinfectant Wipes

DP 20: Laundry Scent Boosters

DPI: Small Plastic Bottles

DPI: Automotive Oil

DPI: Rigid Containers of Soap

DPI Drop Packing System: Pressurized Aerosol Cans

CHL: Adhesive Tape

Drop Packing System: Carpet Cleaner

Alphapack 10: Oral Rinse Products

Multi-Conveyor Alphapack: Bags of Sweetener

SPP / HL Palletizer: Oreos

Alphapack 8/10: Pillow Bags of Coffee Bags

SPP: Packets of Paper

Alphapack 15: 32-Ounce Spray Bottles

Alphapack: Different Size Plastic Bottles

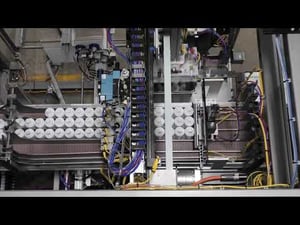

Alphapack 8 Packing 10 Liter F-Style Jugs

Alphapack 8 Packing 10 Liter F-Style Jugs

Ergopack 20

Robotic Palletizer with Integrated Phoenix Stretch Wrapper

Robotic Palletizing System with Integrated Stretch Wrapper

DePalletizer

ErgoPakPal: Boxes of Fishing Sinkers

Robotic Ergopack System: Tubes of Adhesive

Robotic Case Packing System: Bags of Shredded Cheese

RCE

DP 20: Chemical Cleaner

DPI: Bottles of Juice

Ergopack: Stand-up Pouches of Pretzels

Sanitary Ergopack Semi-Automatic Case Packing

OneWrap+

ProWrap

ProWrap+

BeeWrap+ Set Up

TF 40G

.jpg?width=300&name=hqdefault%20(1).jpg)

Combi Offers Broad Selection of Services for National Accounts

Combi Offers Sanitary Barrier Option

Combi Customer Testimonial - Plastic Cutlery

Robotic Packaging and Automation Innovation with Combi

Combi Meat & Poultry Industry Packaging Equipment

Dual Line Pick and Place Case Packing System with Robotic Palletizer: Paper Packets

EZ Pal Robotic Palletizer

Viper Strapping Tool by Siat

GT-Xtreme Strapping Tool by Siat

2-EZ XL 10 with Tall Cases

Video Box Title

Description. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et

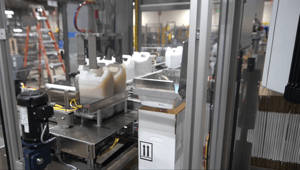

SPP Packing F-Style Jugs of Herbicide

SPP Packing F-Style Jugs of Herbicide

Alphapack 10 Packing 2.5 Gallon F-Style Jugs

Alphapack 10 Packing 2.5 Gallon F-Style Jugs

Talk to Combi about Your Packaging Needs

Have questions for our team? Fill out our contact form below or call us at 1.800.521.9072.

GET IN TOUCH WITH US

WANT TO FIND OUT WHAT COMBI CAN DO FOR YOU?

Need a Quote?

REQUEST A QUOTE

Stay Connected

.png?width=161&name=ProWrap%20(1).png)