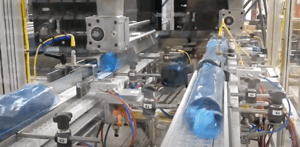

SPP PICK AND PLACE CASE PACKER

The Combi servo pick and place case packer is a top load system featuring heavy duty linear servo motors capable of 25 picks per minute. Integrated with the E-series case erectors, the servo pick and place case packer has a compact footprint for fitting into the tightest packaging lines.

- Description

- Features

- Specifications

- Downloads

YOUR PRODUCT, OUR SOLUTION

The Alphapack and SPP both handle the widest range of products from flexible bags, chipboard cartons, shrink wrapped packages, to light weight, semi-solid products or any other package that requires special handling, orientation, or precise placement in multiple layers.

Combi's case packing systems are used by a wide range of industries. View a full list of our industries served.

If you have the exact details for your packaging needs, please complete the formal Request For Quote Form.

Features

- Heavy duty all welded tubular steel frame with lifetime guarantee

- Compact footprint when integrated with E-series case erector

- Many collation methods for product grouping and orientation

- Up to 25 picks (product layers) per minute

- Quick changeovers with minimal change parts

- No tool crank adjustments with numbered scales

Options

- Servo driven rotary head

- Dual or triple pick heads

- Stainless steel frame and/or washdown components

- Stand-alone system without case erector

- Electrical control integration

- 3rd axis step indexing conveyor available

- Full safety guarding with hinged doors and interlocks

- Product diverter for non-round products

| Model | SPP | SPP Dual |

| Case Size Min (LxWxH) |

8 x 6 x 5" (203x152x127mm) |

8 x 6 x 5" (203x152x127mm) |

| Case Size Max (LxWxH) |

24 x 16 x 18" (610x406x457mm) |

24 x 16 x 18" (610x406x457mm) |

| Speed: Cases Per Minute* | 20 cpm | 20 cpm |

* Speeds are case size dependent

.png?width=161&name=ProWrap%20(1).png)