Combi Packaging Systems

A Symphony of Efficiency:

Combi’s Integrated Packaging Solutions for Perfect End-of-Line Automation

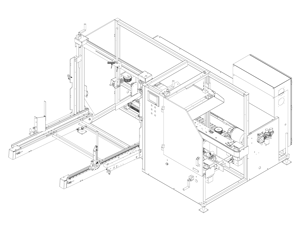

In today's competitive market, optimizing your packaging equipment systems are not just an option—it’s a necessity. Combi Packaging Systems offers a comprehensive range of end-of-line automatic packaging systems designed to enhance every aspect of your packaging operation. From case erecting to stretch wrapping, our modular systems work seamlessly together to deliver unparalleled efficiency and reliability.

Modular Integration

Our end-of-line packaging equipment solutions address the full spectrum of packaging needs through a breadth of products and capabilities that are unmatched in the industry:

- Case Erecting: Jumpstart your packaging process with precision and speed, laying the foundation for enhanced productivity.

- Case Loading: Automated precision ensures each product is perfectly placed, maximizing throughput and minimizing manual labor.

- Case Sealing: Secure sealing guarantees the integrity of your products, enhancing quality and protection during transit.

- Case Palletizing: Configurable and flexible, our palletizing solutions reduce labor demands and mitigate the risk of workplace injuries associated with this unpleasant task.

- Stretch Wrapping: The final step ensures your products are securely contained and ready for shipment with optimal protection.

Each module is designed to function independently or as part of a coordinated system, allowing for flexibility in integration and scalability. Whether you need one component or the entire suite, Combi’s solutions are engineered to grow with your business needs.

The Combi Advantage

Choosing Combi’s end-of-line packaging systems means investing in a partnership that extends beyond the purchase. Our integrated systems not only streamline operations but also bring significant labor savings and increase in production speeds. By reducing human intervention, we lower the risk of injury and boost overall workplace safety. The consistency that comes from automation enhances overall quality and ensures that packaging defects are kept to a minimum, significantly reducing product damage and customer complaints.

Perhaps most importantly, choosing Combi as your single supplier for end-of-line systems eliminates the complexities associated with managing multiple vendors. This unified approach simplifies maintenance, streamlines support, and ensures that all components of your packaging line are perfectly synchronized, reducing downtime and operational risks.

COMBI PACKAGING EQUIPMENT

When you work with Combi, we give you custom options. Whether you have a packaging challenge or simply need to get your products packaged efficiently and cost-effectively, we’re here to help.

.png?width=300&name=HTF-10%20-%20FRONT_transparent_0%20(1).png)

-1.jpg)

Packaging Equipment Markets We Serve

Combi Packaging Systems can design, build, and ship customized industrial packaging machinery for a broad range of markets.

COMBI PACKAGING EQUIPMENT PARTS & SERVICE

COMBI Insights

The Project Management Process Is the Key to On-Time Machine Delivery

What to Expect When the End-Of-Line Packaging System Arrives

When End-Of-Line Packaging Machinery Meets Sanitary Washdown Requirements

COMBI NEWS & EVENTS

and designs from Combi.

Combi’s Commitment

At Combi, we are committed to your success. Our turnkey solutions are backed by comprehensive support and service that ensure smooth operations from installation through ongoing maintenance. Partner with Combi and experience the peace of mind that comes from knowing your end-of-line systems are in expert hands, allowing you to focus on what you do best—growing your business.

.png?width=161&name=ProWrap%20(1).png)

.jpeg?width=300&name=AdobeStock_439714737%20(1).jpeg)

![Updated_Sales Traing Room[36]](https://44782104.fs1.hubspotusercontent-na1.net/hub/44782104/hubfs/Updated_Sales%20Traing%20Room%5B36%5D.jpg?width=300&name=Updated_Sales%20Traing%20Room%5B36%5D.jpg)